Fridays workshop was a continuance on the workshop on Thursday. We concluded that the prototype didn’t add any value to the specific game (ping pong) and so the workshop was to re-develop the controller.

So we as a group decided that the pedal controller didn’t work as intended. We wanted to create a controller that could be controlled by using your feet and balance. Since we didn’t have much time last session we didn’t incorporate the “balance-function”. Therefore we only did a simple up/down controller. We came to the conclusion that the design was ok, but the functionality was poor. The controller required to much force and was sized to bigger shoe size.

The focus was to try to fix all these issues but most importantly get the functionality to work as we intended. To reach that goal the sensitivity and precision had to be increased in the pedal. Now as quick prototype we used bunched up some copper tape into a dense ball. This acted as the switch which made connection between the two copper strips which in turn were hooked up via wire leads to arduino, completing the circuit.

The controller consisted of two pieces of paper between a 1,5-2 cm thick plastic foam. Which was surprisingly resilient against wear and tear. There was nothing wrong with the foam or the structural integrity of the controller, only the function had to be tweaked in order to increase the precision. This value had to be carefully investigated and tuned. A controller has a game to be matched against. The sensitivity and response of an controller is key in order to have a fluid and interactive experience but we, as previously mentioned, felt we were way below the acceptable level for both areas.

As the controller was used multiple times, the copper ball got more and more squished together into a denser ball, yielding a even worse connection or no connection at all. So we started to take apart and explore the role of the ball and try to redo it to something that isn’t in the risk of being defective once it has been used a couple of times.

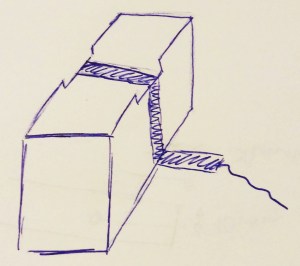

The toe and heel part was replaced with object in figure 2, rest of the plastic foam was used a center piece to put all the weight of the foot/body. The sides of the object are a little bit higher than the center part where the copper strip is located mimicking a button.

When implemented it seemed to work a bit better than the first revision. Still some amount of force had to be applied but not as much as before. The precision can be worked on but I don’t think it’s possible to improve it by making it with foam/paper/copper. The controller has either a connection or not, so the travel is a bit unimportant for the user to think about. The user will always use more force than needed just to be safe that the controller makes a connection. Inevitably pushing the design back to square one, but so far we know that the force applied to it can be adjusted in a limited. Replacing the plastic foam and experimenting with different material could be a solution for future development.

As an approach in future (and this comes also with a bit experience) is to collect and sample a variety of different materials available and just play around with their physical attributes. In a way it will give more understanding about the material and the prototype can be developed with a bit more certainty.

This week has introduced a mix of static and dynamic work. With the coding exercises I’m limited to explore the digital possibilities of a animation library. Other than showing of interesting animated elements, I don’t see so much use of the coding in the physical workshop we had this week. Maybe if a game or some digital prototype has to be developed then maybe it will be useful?